The history of Australian car manufacturing dates back to the late 19th century, when horse-drawn carriages and steam trains were the norm for getting from A to B. The industry has endured a rollercoaster journey, and despite its recent setbacks, can still be revered as a defining point in Australian history.

Australia's relationship with cars predates our federation, and represents an important chapter of our manufacturing past, not only by the progression of these amazing machines, but how this effective mode of transport changed the livelihoods of many Aussies.

We've taken a look back at the automotive industry's lifespan in terms of local production, and how it helped shape our nation. Come and explore Australia's car manufacturing history with this 'exhaustive' compilation of everything four-wheels — including brands, export locations, facts, makes and models.

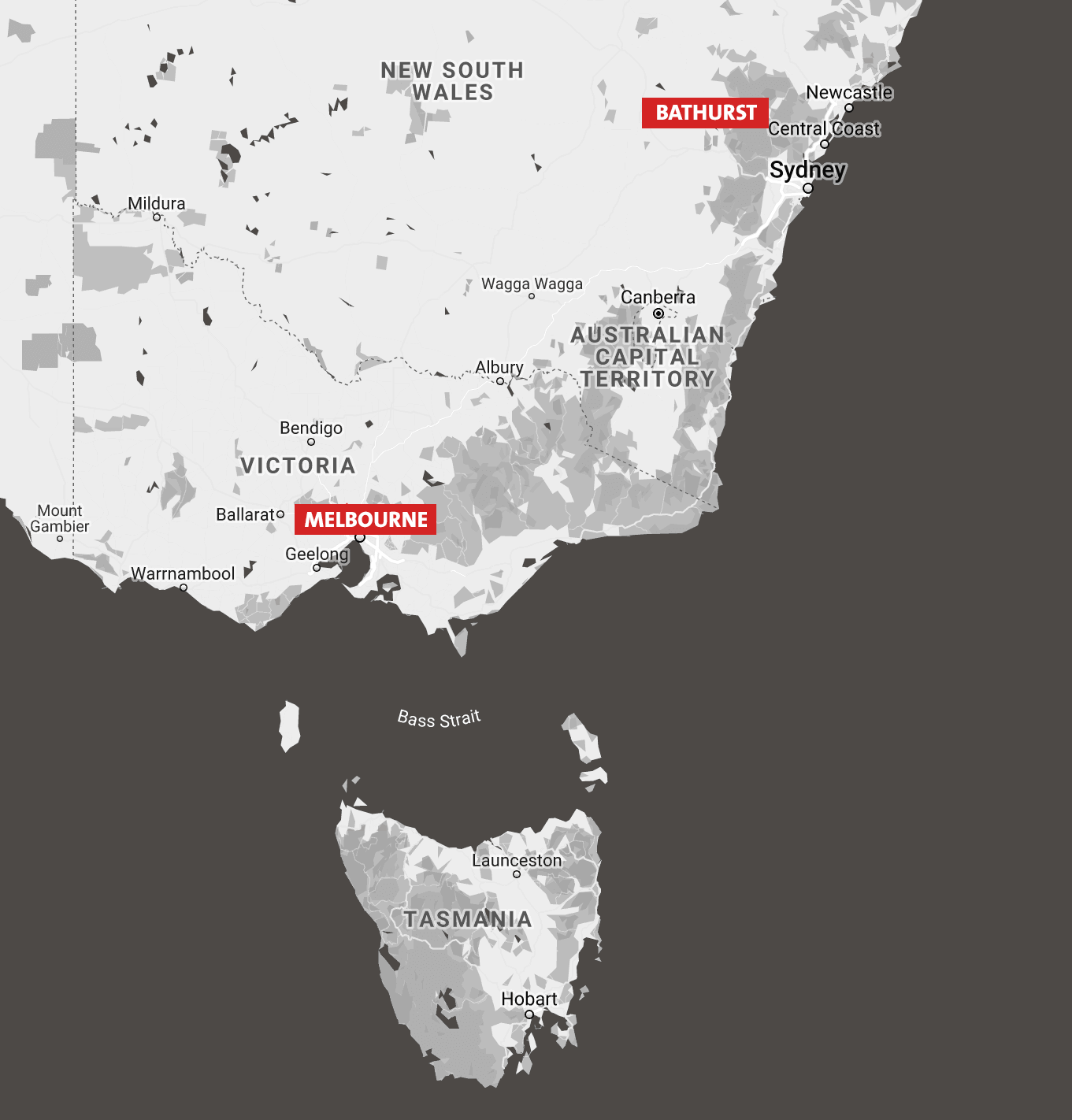

Elizabeth Street, Melbourne, looking north from Flinders Street, circa 1900

source: State Library Victoria

The birth of Australian car manufacturing

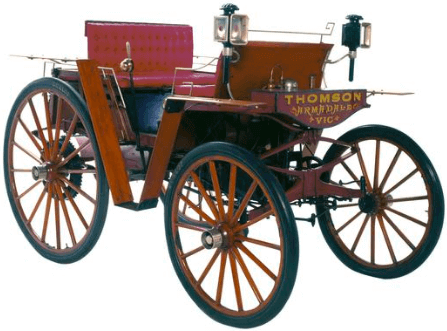

Australia's first car was a steamer built in 1896, named the 'Thomson Motor Phaeton'.

source: Steam Car - Herbert Thomson, Armadale, Victoria, 1898 Copyright Museums Victoria

In 1896, Herbert Thomson and Edward Holmes of Melbourne introduced Australia's first steam car nicknamed 'The Phaeton'. This newly developed vehicle managed to drive a distance of approximately 790 kilometres, at an average speed of 14 kilometres an hour. It took over 56 hours to complete the journey — a feat which stimulated further motor-vehicle development across the country.

As the demand grew for automobiles in Australia, Harley Tarrant developed the country's first petrol-driven car in 1901.

It was Tarrant's prototype that is widely considered our nation's first car, due to its petrol powered engine, which had a Benz imported motor.